I’m now convinced that I also should be able to “scratch build” the stern decorations.

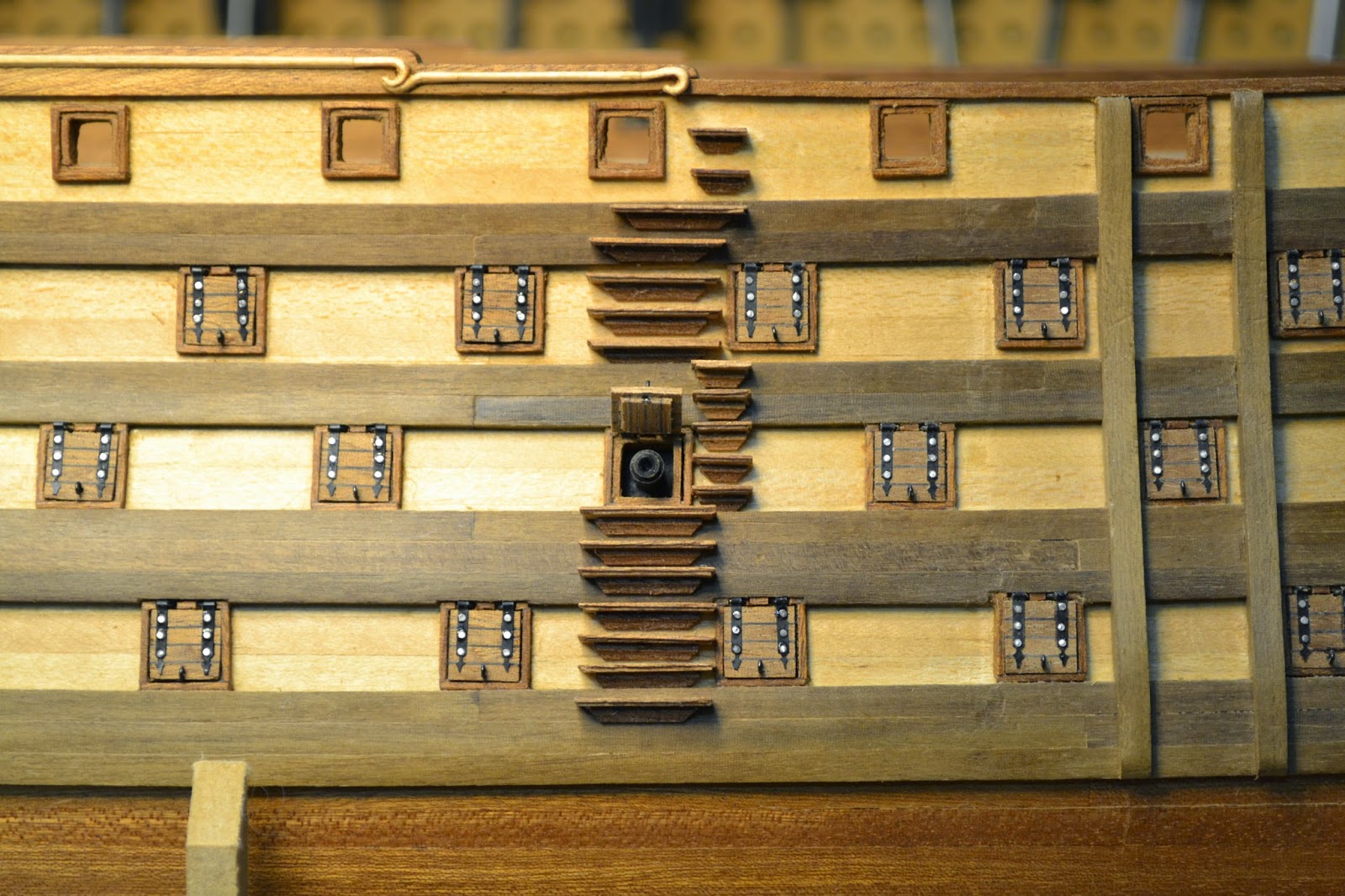

But first the ladders, and, ..“off course” .. I just couldn't resist and had to add a bit more detail.

I wanted an “edge” around the rungs to add more detail and to create a slimmer look.

To achieve this I milled a 2 mm routerbit (with the appropriate depth and height) into my primitively made guide and milled the edge in the list.

After cutting the rungs they became too small to hold them by hand, so I made a “tool” to hold them and milled the remaining edges.

I milled an groove with a round routerbit to get a nicer base shape for the rungs

Assembled all the individual pieces.

..And placed them ..